Beatus Cartons – case study

Beatus Cartons choose Roland DG to launch new Innovation Centre

Sales Director, Clive Stinchcombe explains why Roland DG has been essential in making the new Innovation Centre a success.

Family owned and run Beatus Cartons is a design and manufacture company that produces creative and versatile cartons for a range of products; from counter displays and confectionery boxes to shelf-ready packaging. Specialising in folding cartons, including customer samples and small promotion items, the Wales based business is one of the only companies in the UK to provide this type of packaging on solid board, litho laminated and plastics – all at one facility, by the same team of professionals.

Following 70 years of professional trading, Sales Director, Clive, and Managing Director, Steven Lord, presented the idea of Beatus Cartons launching an Innovation Centre, which would serve as an environment for existing and potential customers to explore packaging ideas and then bringing these to life utilising the facilities. The Innovation Centre would allow individuals to work with the company’s packaging specialists to mock-up initial concepts, before these were produced as samples.

While planning the concept for our new Innovation Centre, we quickly realised that having the ability to offer instant prototypes and samples was essential

Speaking about how the Innovation Centre came to life, Clive said: “While planning the concept for our new Innovation Centre, we quickly realised that having the ability to offer instant prototypes and samples was essential. We therefore needed to invest in a device that could produce accurate product samples quickly and easily. We searched the market for a machine with the best performance, quality and customer support and soon enough, our research established Roland DG to be the stand out option.”

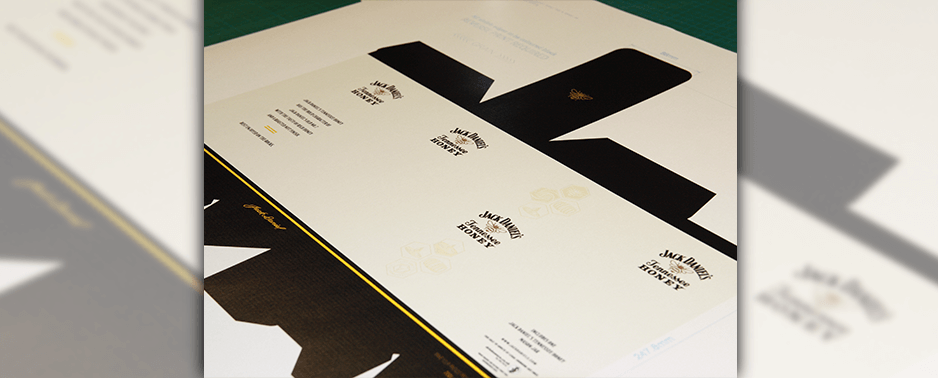

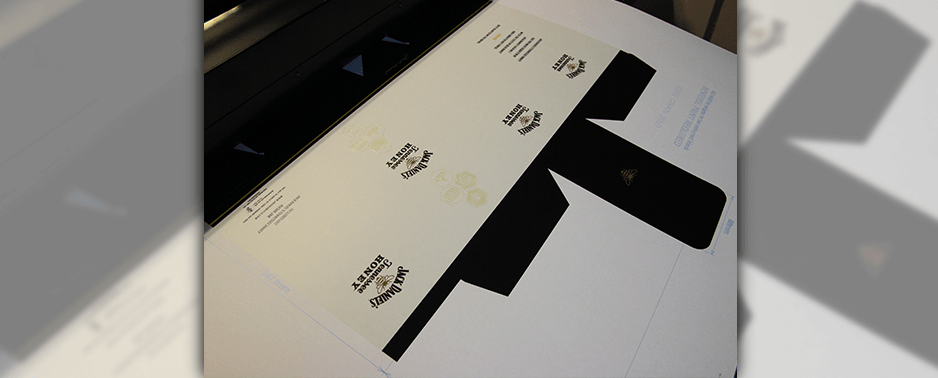

In October 2015, to facilitate the impending launch of the Innovation Centre, Clive and his team purchased the Roland DG VersaUV LEC-540 UV inkjet printer/cutter from Roland DG Authorised Dealers – Revolution Digital. Printing in CMYK plus white and gloss, the LEC-540 had the ability to print colour-accurate packaging prototypes that were virtually indistinguishable from the finished product. The LEC-540 was able to create remarkably rich effects including matt and high-gloss finishes across a range of textures and patterns, including the ability to simulate UV varnish and embossing – essential for the packaging market.

The LEC-540 gave us the ability to instantly respond to a customer’s need with its integrated print, crease and cut functionality

“The LEC-540 gave us the ability to instantly respond to a customer’s need with its integrated print, crease and cut functionality, meaning we could deliver the end-to-end prototype without time-consuming manual intervention. In conjunction with our in-house graphic artist, we were able to work up an initial concept with a customer and then provide them with an accurate sample there and then. This really was essential for the success of this project; without the LEC-540 the entire ethos of the Innovation Centre would have failed,” Clive added.

Prior to investing in the Roland DG machine, Beatus Cartons had to print samples onto standard paper, which often did not truly represent the full substrate of colours the customer would eventually receive. With the ability to print realistic prototypes on virtually any substrate, the LEC-540 was the ideal solution to allow customers to proof designs that would eventually be manufactured at larger volumes. In addition to this, Clive and his team were able to proof additional finishes and coatings – which until the purchase of the Roland DG machine, had to go offsite or require a full machine proofing; helping to save both time and money.

Customers and potential customers alike are blown away by the ability to spend a few hours in the Innovation Centre working directly with our team and to leave with fully printed and cut prototypes

Clive said: “Customers and potential customers alike are blown away by the ability to spend a few hours in the Innovation Centre working directly with our team and to leave with fully printed and cut prototypes. From the customer’s perspective, these samples can then be used for marketing purposes or exhibitions without the additional costs of full manufacture. From my perspective as a Sales Director, by printing samples on the exact substrate that we can manufacture in larger volumes, the Roland DG LEC-540 enables us to showcase our services to customers to help secure new business leads.”

Since launching the Innovation Centre in 2015, Clive and has team has welcomed copious businesses through its doors. This has resulted in new business leads for Beatus Cartons and further strengthened its relationships with existing clients as they work in partnership to achieve innovative and competitive packaging solutions.

One thing is for certain, when considering future proofing requirements, Roland DG is at the top of our list

Following the success of its first year, Clive said: “We have a loyal customer base who value the service and quality we provide. First class response, high quality products and great customer service is what has been the driving force behind the company for over 75 years and we hope that the addition of the Innovation Centre will see us grow and expand even further. One thing is for certain, when considering future proofing requirements, Roland DG is at the top of our list.”